Understanding tractor-trailer sizes is simpler when you separate legal road limits from usable cargo space. At Genron, we build custom semi-trailers. Most sizing mistakes we see begin with confusing measurement terms. This guide focuses on the tractor-trailer dimensions that affect loading, clearance, and safe routing.

Shippers and dispatch teams know that small mismatches in trailer dimensions can cause big problems. A trailer’s interior space, door opening, and deck height determine what you can load. The vehicle’s overall size and turning needs decide where it can go.

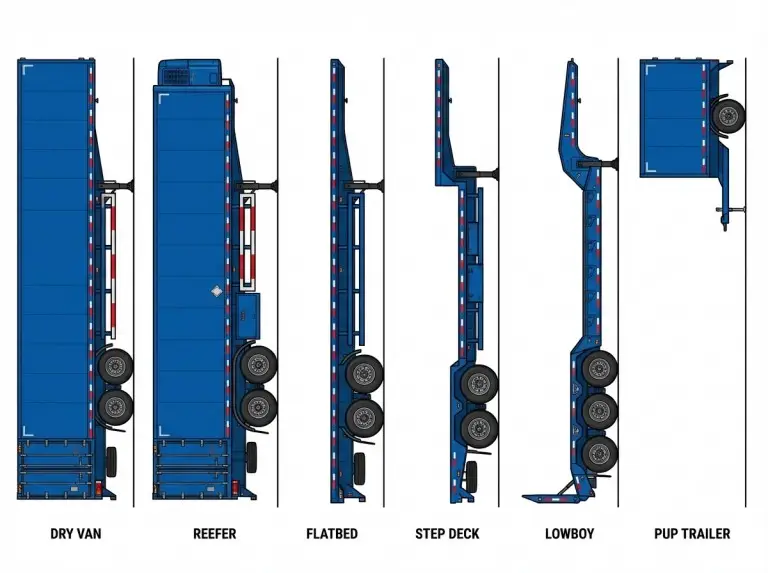

A single number can’t define a tractor-trailer’s size because different trailers solve different problems. A dry van protects cargo from the weather and is ideal for pallet loading. A step deck or lowboy is built for tall equipment. These trade-offs change how you plan routes and manage yard space.

Table of Contents

What “Tractor Trailer Size” Means and How to Measure It?

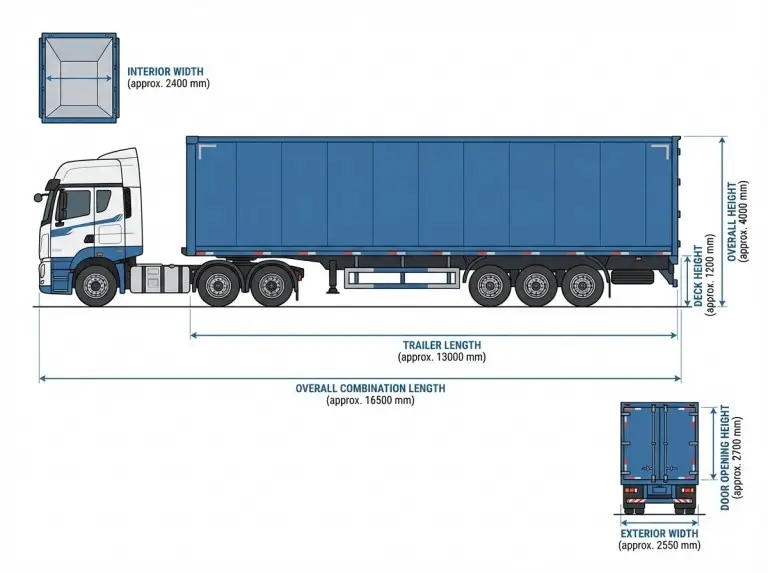

An accurate discussion about tractor-trailer size requires everyone to use the same measurement points. When teams search for 18 wheeler dimensions, these are the exact measurement points they should confirm first.”Overall length” usually means from the front of the tractor to the rear of the trailer. “Trailer length” is just the length of the trailer, not including the tractor.

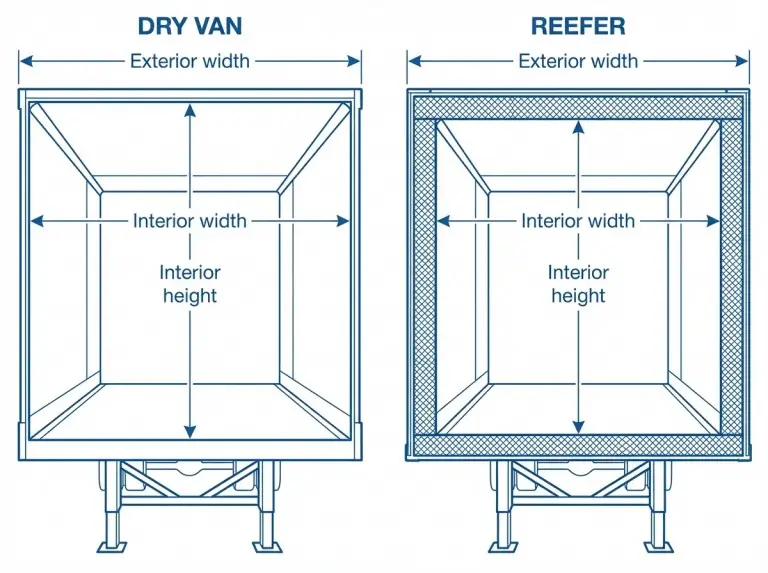

Exterior width and interior width are different numbers used for different decisions. Exterior width helps with lane and route rules, while interior width determines if cargo fits between the walls. Similarly, interior height dictates freight stack height, but the door opening height controls what can physically get inside.

Flatbed-style trailers use different measurement terms than enclosed box trailers. Deck height, the distance from the ground to the deck surface, affects the legal height of your cargo under bridge clearance limits. Available load height is the space between the deck and the route’s safe overhead clearance.

Our conversations with customers are more efficient when we get five key numbers early on. These are trailer type, trailer length, exterior width, clearance height target, and the cargo’s longest dimension. These five inputs usually tell us if a standard trailer works or if a custom solution is needed.

Standard Size Limits: Width, Height, and Typical Combination Length Range

Most size planning starts with width, height, and trailer length. These limits drive route access and dock fit. In the U.S., the most common exterior trailer width is 102 inches (8.5 feet). Fleets also run older or specialized equipment that may be narrower, so you should always confirm the actual width of each trailer.

Height is often a route problem before it’s a trailer problem. Many operators use 13 feet 6 inches as a practical “safe standard” for highway clearance. Some regions allow more height under specific conditions. Local roads, industrial sites, and older bridges can have lower clearances. This is why route verification is important when your freight is tall.

Trailer length is often the main number people focus on, as 48-foot and 53-foot trailers are common. A 53-foot dry van is popular for general freight, and many warehouses are set up for that size. For a quick spec reference, see our 53′ truck trailer dimensions page for typical exterior and interior measurements.Overall combination length is less consistent as a single national number. Planning often depends on trailer length plus the actual yard and turning space available.

Size and weight rules are connected. You should always check weight details against the specific route and axle setup. The U.S. interstate gross vehicle weight limit is 80,000 pounds for standard setups. Overweight moves typically need permits and routing restrictions. If a project requires maximum payload, treat published limits as starting points that still need to be verified.

Main Trailer Types and Their Typical Uses

The trailer type, more than the tractor, determines deck height, interior space, and loading method. A dry van and a reefer might have similar outside dimensions, but a reefer’s insulation and cooling hardware reduce its usable interior space. A flatbed and a step deck can have similar lengths, but their deck heights change what a “legal height” load can be.

|

Trailer Type |

Common Lengths (U.S.) |

Typical Width Notes |

Height / Deck Notes |

Typical Uses |

|---|---|---|---|---|

|

Dry Van |

48 ft, 53 ft |

Often 100–102 in |

Interior height often ~110 in (varies) |

Palletized general freight, boxed goods |

|

Reefer |

48–53 ft |

102 in exterior, narrower interior |

Interior space reduced by insulation |

Produce, frozen food, pharmaceuticals |

|

Flatbed |

Often 48 ft (53 ft exists) |

Width varies by spec |

Deck often ~5 ft from ground |

Steel, lumber, machinery, side/top loading |

|

Step Deck |

Common in similar lengths |

Width varies by spec |

Lower deck closer to ~3 ft |

Taller freight under clearance constraints |

|

Lowboy |

Varies by application |

Width varies by spec |

Very low deck between neck and axles |

Construction equipment, high-profile loads |

|

Pup Trailer |

Often ~28 ft |

Varies |

Used in doubles/triples configurations |

LTL hub freight and routing flexibility |

Dry Van

A dry van is the go-to choice when freight needs weather protection and dock loading. These trailers are common in 48-foot and 53-foot lengths. Many are built to the standard exterior width for major highways. Shippers often plan around pallet counts, and a 53-foot dry van can typically hold 26 standard pallets.

Sizing mistakes often happen when teams confuse interior and exterior dimensions. The inside width and height can vary by maker, flooring, and liner design. A load plan should always use the specific trailer’s interior measurements when cargo clearance is tight.

Reefer

A reefer’s main job is temperature control, so usable space is a secondary concern. Reefer trailers often have the same exterior width and similar lengths as dry vans, but insulation makes the interior narrower. The cooling unit and insulation also add weight, which can reduce payload compared to a dry van with the same gross weight limit.

Reefer sizing must account for airflow needs, not just floor length. Some freight needs air channels or spacing that reduces how much you can pack in. When getting a reefer quote, confirm the interior width and height instead of assuming they are the same as a dry van’s.

Flatbed

A flatbed offers loading flexibility because you can access it from the side, top, or rear. They are often 48 feet long, but 53-foot versions are also available. The open deck allows you to haul irregular shapes, but it also makes “height” a major planning issue.

Flatbed height planning starts with deck height plus cargo height. A typical deck is about 5 feet off the ground, which shows how quickly tall freight can exceed clearance limits. When freight is close to the height limit, many teams switch from a flatbed to a step deck or lowboy to avoid a violation.

Step Deck (Drop Deck)

A step deck lets you haul taller cargo without changing its physical height. The lower rear deck sits closer to the ground than a flatbed’s, giving you more vertical space under the same overhead clearance. This is why operators often say the deck is “closer to 3 feet” from the ground.

When discussing step deck sizing, confirm where the freight will sit. The upper and lower decks have different lengths, and axle placement affects weight distribution. A good plan will confirm the deck lengths and tie-down points for that specific trailer.

Lowboy

A lowboy is designed to haul equipment where the deck must be very low. The deck sits between the gooseneck and the rear axles, which lowers the overall loaded height for tall machines. Lowboy moves also frequently involve permits and route limits when the load is oversized.

Lowboy sizing is usually driven by the equipment’s dimensions and how it will be secured. The machine’s width, height, and loading method determine if the ramp angle and deck design will work. When customers ask us about lowboy sizing, we focus on equipment shape and route realities before looking at standard dimensions.

Pup Trailer

A pup trailer is a shorter trailer used in “doubles” or “triples” setups. The common 28-foot length is standard in less-than-truckload (LTL) operations. Using multiple trailers adds flexibility for sorting freight at hubs, but it also changes turning behavior and route permissions.

Pup trailer sizing is less about maximum volume and more about how it fits into a network. Yard space, dock layout, and coupling methods determine if a multi-trailer operation is efficient. Route checks become even more important as setups get more complex.

Picking Sizes for Loading, Clearance, and Route Fit

The right tractor-trailer size is the one that clears your biggest obstacle, not the one that looks standard on paper. Warehouse docks often require enclosed trailers because they need a standard door position and a secure seal. Flatbed operations often need open access because side loading or crane loading is more important than dock use.

Clearance planning should start with the smallest opening the load must pass through, whether it’s a warehouse door, a low bridge, or a site gate. A plan should compare the cargo height on the trailer deck to the route’s lowest safe clearance, using a safety buffer your route team can defend.

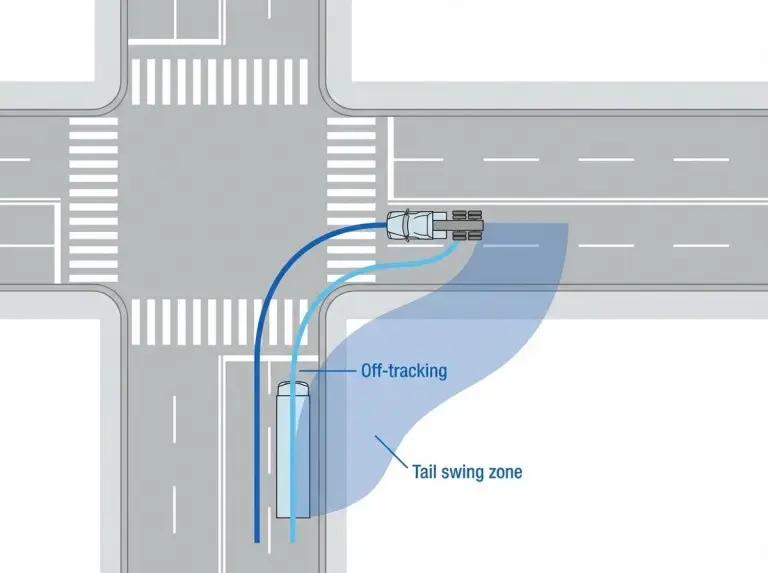

Treat turning and yard fit as sizing problems, not just driver skill issues. A longer trailer needs a wider turn, and the trailer’s wheels will cut the corner more sharply. A site walk or a look at satellite images can show if a 53-foot trailer can enter, turn, and dock without risky moves.

Cargo fit depends on interior dimensions, not marketing names. A “53-foot trailer” doesn’t guarantee a single interior length, width, or door opening height across all models. We recommend confirming interior dimensions from the specific unit when freight has little room to spare.

Maneuverability and Safety

Long vehicles create cornering and blind-spot risks that you can only manage with good planning, not late reactions. Off-tracking means the trailer’s wheels follow a tighter path than the tractor’s wheels in a turn. This is why professional drivers swing wide before a right turn, especially at tight city corners and dock approaches.

Tail swing is the opposite motion. When a tractor turns sharply, the rear of the trailer can swing outward and hit nearby objects. Tail swing is a hazard at loading docks and on the street, so a site plan should include space behind and beside the trailer.

Stopping distance increases with weight and speed, and wet or icy roads add to the risk. A fully loaded tractor-trailer needs much more room to stop than a passenger car at highway speed. Car drivers can reduce risk by not cutting in front of trucks and leaving extra space ahead.

Blind spots are large because the trailer blocks sight lines. The right-side blind spot is often bigger than drivers expect, and the area directly behind the trailer is a complete no-view zone for the driver. A simple rule for other drivers is to avoid staying beside the trailer and to keep the truck’s mirrors in your view.

Confirm the Right Size Before You Book or Load

A short, repeatable checklist prevents most loading errors and last-minute route changes. The list works best when one person owns the numbers and uses the same measurement method with every team.

- Confirm trailer type and loading method (dock, side, top, rear) first.

- Decide if the critical limit is interior space, door opening, or route clearance.

- Confirm cargo length, width, and height using its maximum packaged dimensions.

- Confirm the trailer’s interior length, width, and height if cargo clearance is tight.

- Check the door opening height and any hardware that might get in the way.

- Check flatbed or step deck height when overall loaded height is close to clearance limits.

- Confirm overall loaded height (deck height + cargo height) and check it against the route.

- Confirm site access limits like gate width, yard turn space, and dock approach angle.

- Confirm axle setup and weight distribution when payload is near gross limits.

- Confirm permit needs when any dimension exceeds standard rules.

Conclusion

You can choose tractor-trailer sizes with confidence when you match the trailer type, usable space, and clearance limits before booking a load. Standard dimensions like common widths and trailer lengths help with planning. However, the final decision requires the specific trailer’s interior measurements and the route’s tightest restriction. When your sizing method stays consistent, your team can reduce surprises and prevent reloads.

At Genron, we treat sizing as an engineering talk, not a guess. Our approach starts with clear measurement terms. We then match the trailer type to the real challenge at the dock, on the route, or at the job site. When you use the same process, tractor-trailer sizes become a tool for efficiency, not a source of risk.

FAQ

What is the typical height of an 18-wheeler on the road?

A common assumption for highway clearance in the U.S. is about 13 feet 6 inches for overall vehicle height. Many fleets use this as a safe standard, but local roads can be lower. A route plan should confirm the lowest clearance on the path when freight is tall.

How wide is a semi-trailer in standard operation?

A widely used standard exterior width is 102 inches (8.5 feet) in U.S. operations. Older equipment may differ, so you should verify the specific trailer’s width. Interior width is narrower and should be used for cargo fit decisions.

How long is a tractor-trailer combination?

A tractor-trailer combination’s length varies by tractor style and trailer length. Operations often plan around 48-foot or 53-foot trailers, then confirm site turning space. A dispatch plan should treat overall length as a range that must fit the actual yard and route.

How much can a 53-foot dry van carry?

A 53-foot dry van is often planned around pallet counts, with 26 standard pallets being a common benchmark. Payload capacity depends on trailer weight, tractor weight, and the route’s gross weight limit. A load plan should verify weight and axle distribution when cargo is heavy.

What is a “kingpin to rear axle” requirement?

This is a state or route-level rule that limits the distance from the trailer’s kingpin to its rear axles. The rule affects turning and can impact axle slider position and weight distribution. Carriers should verify the requirement for the operating state before setting axle positions.