Clear terms stop wrong builds, unsafe loads, and costly fixes. This works only if everyone uses words the same way.

At Genron International Trade, we build and customize semi flatbed trailers. We see a pattern. Most quality disputes start as language issues, not steel problems.

This guide helps buyers, fleet managers, and operators. They read spec sheets, compare setups, and talk with makers or service teams.

I focus on flatbed terms you meet in drawings, quotes, inspections, and daily work. I add enough context to help you pick and maintain the right trailer.

Table of Contents

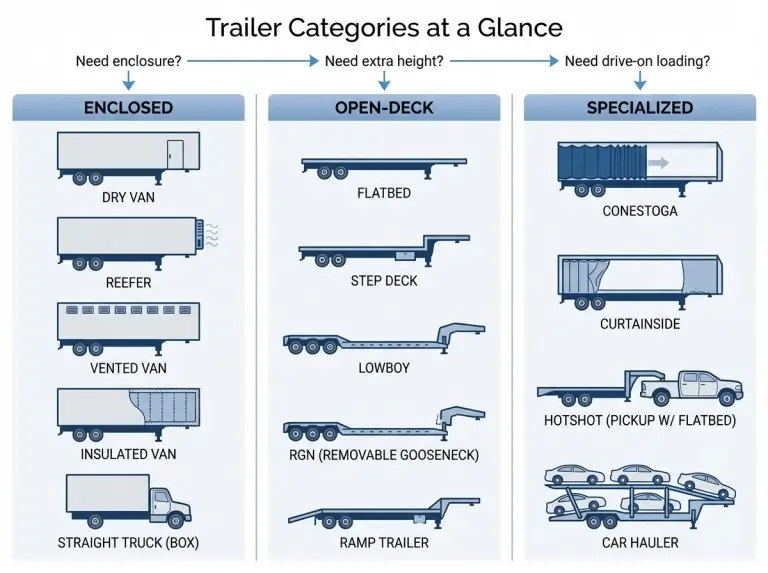

Main Types of Flatbed Trailers and Their Typical Uses

Pick the right flatbed type by matching deck height and usable deck length to the load’s height, length, and loading method.

We build several flatbed setups. Each solves a different problem, like clearance, length, approach angle, or cargo shape.

| Flatbed type | Typical use | Why it’s chosen | Watch-outs |

|---|---|---|---|

| Standard flatbed | General freight, pallets, bundled materials, equipment that doesn’t exceed height limits | Simple, versatile, easiest to maintain | Tall loads may hit legal height limits |

| Extendable flatbed | Long cargo (steel beams, poles, pipes, prefabricated components) | Adjustable deck length for overlength loads | Load balance and securement planning become more critical |

| Drop deck (step deck) | Taller equipment that needs a lower deck to stay within height limits | Lower deck section increases usable load height | Deck transitions affect loading approach and tie-down routing |

| Double drop | Very tall/heavy machines needing a “well” | Lowest deck “well” for maximum clearance | Loading geometry and ramp setup are more demanding |

Standard Flatbed

A standard flatbed fits best when cargo height is easy to handle and you want a simple, adaptable deck.

It offers an open, level load surface that supports side loading, crane loading, and mixed cargo shapes without special deck drops.

When you see “standard flatbed” in a quote, confirm deck length, deck width, and the number and spacing of securement points. These details decide if the trailer acts flexible or becomes a daily hassle.

Extendable Flatbed

An extendable flatbed works well when cargo length changes per job and a fixed deck causes risky overhangs.

The frame telescopes to extend the deck. This supports long loads with better weight spread than forcing them on a fixed trailer.

When you specify this type, clarify usable extension range, locking positions, and how extension affects tie-down spots. Long loads amplify balance errors, so axle placement and load planning matter more.

Drop Deck (Step Deck)

A drop deck fits right when cargo is tall enough that a standard deck exceeds height limits, but you want a simple platform.

The deck drops after the front, giving more legal height room for equipment and crates.

In specs, note upper deck length, lower deck length, and deck height per section. These decide cargo placement and if loading gear clears the step safely.

Double Drop

Use a double drop for extreme cargo that is very tall and needs the lowest deck area, the well, to stay within clearance limits.

The front and rear are higher, and the center well holds the machine.

In use, double drops need careful planning for loading shape, ramp choice, and securement routing because deck heights change. If cargo has low ground clearance, confirm approach angle and breakover before setup.

Further Reading:Step Deck vs. Flatbed Trailer

Glossary by Trailer Structure: Deck, Rails, and Frame Members

Most structure terms matter because you use them to spot missing features and avoid issues in orders.

We review flatbed requests and translate customer words into structure terms from design and production.

Deck, decking, and surface options

The deck is the load-carrying surface, and decking names the material or system.

Options include hardwood, steel plate, aluminum, or composite systems. Each affects weight, traction, and maintenance.

If loads involve chain contact or point loads, deck choice affects damage rate and long-term flatness.

When you request deck material, confirm thickness or plank section, fastening method, and expected wear.

Side rail, rub rail, stake pocket, and winch track

A side rail edges the structure and defines the deck perimeter. It supports securement features.

A rub rail protects along the side, absorbs impacts, and acts as a barrier between cargo gear and the main structure.

Stake pockets are openings along the side where you insert stakes or side kits. They also serve as reference points for tie-down positions.

A winch track is a rail system that lets winches slide and lock along the side for flexible securement.

Headboard vs bulkhead (front protection terms)

A headboard is the front barrier, often used like “bulkhead” in casual talk. It protects the tractor and helps control forward cargo shift.

In specs, bulkhead may focus on load control, while headboard acts as a protective panel and mounting platform.

For flatbeds, define what you need: protect the cab, mount tools or winches, or provide rated restraint.

If you need restraint, ask for the design intent and confirm it matches your load risk.

Main beam, crossmember, and outrigger

Main beams run lengthwise and carry most bending loads. You see styles like I-beam or box beam. The choice affects strength-to-weight and how it handles focused loads.

Crossmembers run across the width and spread deck loads to the beams. Their spacing and type influence deck support and fatigue life.

An outrigger extends outward from the main frame to support wider load areas or edge structures. It matters when cargo weight sits near the deck edges.

Glossary by Running Gear: Axles, Suspension, and Wheel-End Parts

Running gear terms decide if your flatbed carries weight legally and rides in a way that protects cargo and hardware.

The best setup depends on payload, road conditions, and how sensitive your loads are to shock.

Single, tandem, spread, and lift axle

A single axle suits lighter trailers or special builds where simplicity and lower cost matter more than max payload.

A tandem uses two axles close together to boost load capacity and stability. It’s a common baseline for medium-to-heavy duty work.

A spread axle places them farther apart, which can improve stability and sometimes allow higher legal weights depending on region.

A lift axle raises when lightly loaded to reduce tire wear and rolling resistance, then lowers when payload requires it.

Air ride vs spring suspension terms

Air ride uses bags to absorb shock and improve ride quality. This can reduce cargo damage and lower vibration-related wear.

Spring suspension, including leaf spring styles, is simpler and rugged. It’s often easier to service in demanding conditions, but it typically rides firmer.

When comparing quotes, don’t stop at “air” vs “spring.” Confirm serviceability, bushing type, ride height control, and how it matches your axle rating. These details decide if the smooth ride lasts on real roads.

Hubs, bearings, seals, and wheel-end basics

The hub holds wheel-end components and supports rotation around the spindle.

Bearings carry the load while allowing smooth rotation. Correct adjustment and lubrication prevent heat buildup and failure.

Seals retain lubricant and keep contaminants out. Seal quality and installation directly affect bearing life.

When you see “wheel-end service” on schedules, it usually includes inspection for heat, play, leakage, and wear indicators.

| Running gear choice | Capacity impact | Ride quality impact | Maintenance note |

|---|---|---|---|

| Single axle | Lower overall | Varies by spec | Simplest layout, fewer wear points |

| Tandem axle | Higher | Better stability | More tires/brakes to inspect |

| Spread axle | Higher (region-dependent) | Often stable | Tire scrub and alignment planning matter |

| Air ride | Varies by rating | Smoother | More components to inspect (air lines, valves) |

| Spring | Varies by rating | Firmer | Robust, predictable service pattern |

Glossary by Ratings and Specs: GVWR, GAWR, Payload, and Load Balance

Ratings are only useful if you understand what’s included and what’s not. That’s where many buyers get surprised.

In our quotes and build documents, we treat ratings as a system. Trailer structure, axles, suspension, tires, and intended use must align.

GVWR, GAWR, tare weight, and payload capacity

GVWR is the maximum allowable total weight of the loaded trailer, including the trailer itself and cargo.

GAWR is the maximum weight a specific axle or axle group can support safely. It’s influenced by axle design, suspension, tires, and wheels.

Tare weight is what the empty trailer weighs, and payload capacity is the cargo weight you can carry: GVWR minus tare.

Always confirm if the quoted tare includes your requested options, because accessories, reinforcements, and deck material change it.

Axle group, load distribution, and practical balance terms

An axle group is a set of axles considered together for load support. It matters because weight must distribute so no group exceeds its limits.

Load distribution describes how cargo weight is placed along the deck and across the width. Poor distribution affects handling, braking, tire wear, and frame stress.

In practice, “balanced” doesn’t mean “centered.” It means each axle group carries an appropriate share under real securement and travel conditions.

If you regularly haul uneven machines or coils, build your spec and securement plan around that reality.

Glossary by Interfaces: Coupling, Brakes, and Electrical Connections

Most roadside issues come from interfaces: connection points, air systems, wiring, and parts that translate motion into control.

If you can name these correctly, you troubleshoot faster and specify compatible systems from the start.

Fifth wheel, kingpin, upper coupler, and gooseneck terms

A fifth wheel is the coupling plate and locking mechanism on the tractor that connects to the trailer’s kingpin.

The kingpin is the hardened pin on the trailer that engages the fifth wheel for a secure, articulating connection.

The upper coupler plate is the trailer’s top area around the kingpin that interfaces with the fifth wheel.

A gooseneck refers to a curved front structure on certain designs to improve clearance and load distribution. Define the exact connection standard to avoid compatibility mistakes.

Air brake vocabulary (tanks, chambers, slack adjusters, foundation brakes)

Air brake systems are common on heavy-duty flatbeds because they provide consistent braking force for large loads.

Air tanks store compressed air, brake chambers convert pressure into mechanical force, and slack adjusters keep brake geometry in the proper range.

Foundation brakes are the components at the wheel end that create friction to stop rotation. Their condition directly affects stopping distance.

When you do inspections, these terms help you report problems precisely instead of saying “the brakes feel off.”

ABS basics and trailer wiring (7-way, harness, junction box, markers)

ABS helps prevent wheel lockup under heavy braking, improving directional control on slippery surfaces.

For electrical, the 7-way connector is the common interface between tractor and trailer. The wiring harness distributes power and signals to lights and systems through a junction box.

Marker lights and reflectors outline trailer dimensions for visibility. Consistent lighting reliability depends on protected routing, sealed connections, and sound grounding.

If you operate in harsh weather or corrosive environments, electrical quality becomes a safety feature, not just a convenience.

How to Use These Terms When You Specify a Custom Flatbed?

The fastest way to get the right flatbed is to treat terminology as your checklist: type, structure, running gear, ratings, and interfaces must align with your load reality and operating conditions.

At Genron, we use this same vocabulary to turn a request into a buildable specification, then into a trailer that performs predictably on the road.

If you use this glossary while reviewing quotes and drawings, you’ll catch the silent gaps that cause delays—like missing securement features, unclear deck specs, misaligned ratings, or incompatible connections.

When you’re ready to discuss a custom flatbed, bring your cargo description, loading method, target payload, and the terms in this guide. We’ll translate them into a clean, production-ready specification.

FAQ

Is “flatbed” the same thing as “step deck”?

No, a step deck is a flatbed-style trailer with a lowered deck section. The term describes a specific configuration.

You choose it when cargo height would be too tall on a standard deck. Always confirm upper deck length and lower deck height because those dimensions drive real usability.

What’s the difference between GVWR and payload capacity?

GVWR is the maximum total loaded trailer weight, while payload is the cargo portion you can carry within that limit.

Payload depends on tare weight, and tare changes with options like toolboxes, reinforcements, and deck material. When you compare quotes, confirm tare under the same configuration.

Are stake pockets tie-down points?

Stake pockets can help with securement setups, but they are not automatically rated tie-down points in every design.

If you plan to use them for restraint, confirm their intended use, reinforcement, and the securement method. For heavy cargo, dedicated rated tie-down points are the safer choice.

Does a headboard guarantee cargo won’t shift forward?

No, a headboard is primarily a protective and supportive structure. It does not replace correct securement.

Cargo securement still requires appropriate straps or chains, correct routing, and enough working load limit for the load. If forward restraint is a critical risk, specify that requirement clearly in your design request.

Is air ride always better than spring suspension?

No, air ride is smoother and can protect sensitive cargo, but spring suspension can be more straightforward and durable in rough conditions.

The better choice depends on road quality, maintenance capability, and cargo sensitivity. In all cases, match suspension rating and service plan to your duty cycle.

What does “spread axle” really change in daily operation?

A spread axle changes stability and weight distribution behavior. It can affect how weight is treated under local rules and how tires wear.

It often improves stability but may increase tire scrub during tight turns depending on setup and operation. If your routes include frequent tight yard maneuvers, discuss this tradeoff before choosing it.