Freight moves fast when the trailer matches the load. But the wrong trailer can slow loading. It adds risk. And it causes damage you can avoid. At Genron, we build semi-trailers. We focus on custom flatbeds. We use the same logic for real shipments every day.

This guide explains main freight trailer types. It shows what each one works best for. It lists typical sizes and payload ranges. And it notes common limits that decide fit in real use. Use it to pick gear faster. Share needs clearly with a carrier or broker.

Table of Contents

Trailer Categories : Enclosed vs Open-Deck vs Specialized

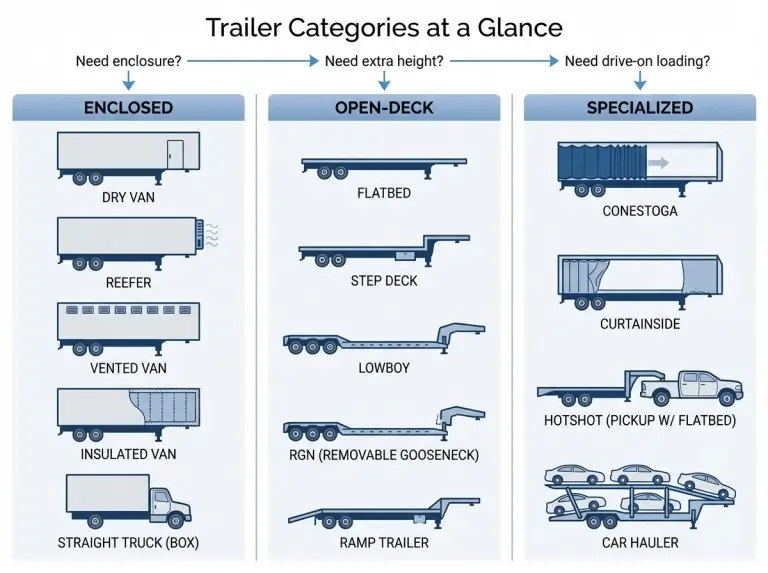

Most trailers fit into three groups. Picking the right group solves most choices. Need weather and theft protection? Start with enclosed. Need side or top access? Have odd shapes? Start with open-deck. Need a special load method? Or built-in protection without a box? Go to specialized.

Enclosed trailers shield cargo from weather. They block road debris. They suit pallet goods and boxes. They load from the rear at a dock. Dry vans and reefers are key examples.

Open-deck trailers handle heavy loads. They take long or tall items. They manage awkward shapes. They allow loading from side, rear, or top. Use forklifts or cranes. Flatbeds fit here. Step decks fit here. Double drops fit here. RGNs fit here. Extendable decks fit here.

Specialized trailers fix one handling issue. They add sliding shields. They add side curtains. They add pickup setups for short hauls. Conestoga fits here. Curtainside fits here. Hotshot fits here.

Remember one rule. Cargo protection needs pick the group. Cargo height and load method pick the exact trailer.

Main Types of Freight Trailers and Their Typical Uses

I use one format for each type. What it is. What it suits best. What limits it. What load access you get. Sizes and payloads are common ranges. They change with specs, axles, and carrier setup.

Dry Van — enclosed general freight for dock loading

A dry van is the default pick for general freight. It stays enclosed. It loads from the rear. It is most common for pallets, boxes, and loose packs.

Most dry vans run 48–53 feet long in U.S. truckload work. Inside limits are about 100–101 inches wide. They reach up to 110 inches high. Payload often hits 42,000–45,000 pounds. They suit retail goods. They suit packed foods. They suit home items. They suit many electronics.

Fixed inside space limits it most. Is freight too tall? Too wide? Needs side loading? Dry van fails even if weight works. Need dock loading? Dry van fits well.

Refrigerated Trailer (Reefer) — temperature-controlled perishables and pharma

A reefer fits when cargo needs set temperature. It has insulated walls. It has a cooling unit. It suits perishable foods. It suits temperature-sensitive drugs.

Reefer lengths match dry vans at 48–53 feet. Inside space shrinks a bit from insulation and unit. Payload often matches dry vans at 42,000–45,000 pounds. It depends on specs and fuel. Reefers set wide temperatures. Many shippers use them to keep product safe on long trips.

It differs from dry van beyond temperature. Reefers add moisture and air flow needs. They need more care at dock to guard cold chain. No temperature need? A reefer can act like a smaller dry van. It stays enclosed. It has different run limits.

Further Reading:Dry Van vs. Reefer: Which is Best?

Standard Flatbed — open-deck versatility for steel, lumber, and equipment

A standard flatbed handles many loads. It gives open access. It allows flexible loading. Is cargo heavy? Irregular? Best with forklift or crane from side or top? Flatbed is first choice.

Common lengths are 48 feet and 53 feet. Legal freight width is near 8 feet 6 inches. Deck sits about 5 feet off ground in many setups. Payload often reaches 46,000–48,000 pounds. It depends on tractor, trailer, and axles.

Flatbeds carry steel. They carry lumber. They carry building materials. They carry crated machines. They carry large parts. Exposure is the trade-off. Cargo stays open. Plan securement. Often add tarps. Access and shape fit win for flatbeds.

At Genron, we customize flatbed semi truck trailers. We target real pain points. Deck length matters. Tie-down layout matters. Winch tracks matter. Lashing rings matter. Rub rails matter. Trailer support for load methods matters. These decide if securement is quick and safe or slow and risky.

Step Deck (Drop Deck) — extra height clearance for taller machines

Step deck is like a flatbed. It lowers deck height. It allows more cargo height. Load too tall for standard flatbed? Step deck is simple fix. It stays under legal height.

Common setup has short upper deck at front. Longer lower main deck follows. Upper deck is about 10 feet. Lower is about 43 feet on 53-foot trailer. Layouts vary. Lower deck sits about 3 feet 6 inches from ground. This allows cargo up to 10 feet 2 inches high in many cases.

Step decks carry farm machines. They carry building gear. They carry factory machines. These are too tall for flatbed. Not tall enough for lowboy. Load access stays good. Plan securement and weather shield like open-deck trailers.

Double Drop (Lowboy) — lowest deck for very tall or high-center loads

A double drop suits tall gear. It needs lowest deck height. It uses two drops. Main well sits close to ground.

Well length is often about 29 feet. Designs vary. Deck height in well is 18–24 inches from ground in common setups. This allows tall gear. Heights reach 11 feet 6 inches to 12 feet 6 inches. It depends on place and setup.

Weight is the trade-off. Lowboys weigh more than flatbeds or step decks. This cuts legal payload before permits. They carry excavators. They carry bulldozers. They carry cranes. They carry similar machines. These exceed heights on other open-deck options.

Removable Gooseneck (RGN) — drive-on loading for self-propelled equipment

An RGN is special open-deck. It eases load of self-propelled gear. Removable front makes a ramp. Gear drives on instead of crane lift.

Standard RGNs have well about 29–30 feet. Cargo heights reach up to 11 feet 6 inches. It depends on setup. Payload varies with axles. Common legal weights are high 30,000 pounds before permits. Extendable RGNs add length. They reach 50 feet of well. Multi-axle setups handle large weights in heavy-haul.

Advantage is load ease. RGNs cut need for site gear. Pickup or delivery lacks cranes or big forklifts? RGN simplifies plan.

Extendable Flatbed / Stretch — long freight that exceeds standard deck length

An extendable flatbed fits long cargo. It exceeds standard flatbed. It fixes length issue. It keeps open load access.

Designs extend from high 30s to 40s feet base. They reach 60–80 feet. It depends on model. Payload is lower than standard flatbed. Structure handles extension and long bends. Axles matter.

It carries long steel. It carries beams. It carries pipes. It carries long parts. Plan support points. Secure load stable across extensions.

Conestoga — open-deck access with sliding tarp protection

A Conestoga mixes open-deck load access. It adds sliding tarp shield. Need flatbed ease? Want repeat weather shield without manual tarps? It fits well.

Conestogas run 48–53 feet. They come as flatbed or step deck. They carry freight hurt by normal tarps. Tarping time slows? It helps. Aerospace parts fit. Sensitive gear fits. Goods with sharp edges fit. They shred tarps.

Cost and supply are trade-offs. They are special. Not as easy to find as standard flatbeds.

Curtainside — side-loading access with weather protection

A curtainside gives weather shield. It allows fast side load. It has rigid roof and end walls. Curtain sides open for access.

Curtainsides run 48–53 feet. Payload is 40,000–43,000 pounds. It depends on setup. They suit building materials. They suit factory parts. Side load boosts dock speed. No need for full dry van box.

Curtainsides differ from Conestogas. Conestoga allows top load in some designs. Curtainside may not. Need overhead crane? Check access before book.

Hotshot — short-haul, lighter open-deck freight with pickup-based rigs

Hotshot trailers are small open-deck. Medium-duty pickups pull them. They suit short-distance work. Speed matters. Flexibility matters. Low entry costs matter.

Many setups use 30–40 feet trailers. Freight weights reach 16,000–16,500 pounds. Sometimes less. They suit light gear. They suit site deliveries. They suit time-sensitive moves. No need for full semi and 48–53 feet trailer.

Capacity limits them. Load heavy? High-volume? Needs large deck? Hotshot fails.

Specs That Decide the Trailer: Dimensions, Payload, and Loading Access

Picking a trailer type gets easy. Gather right shipment facts first. No long talk with carrier. Give clear parameters up front.

Here is our short must-have checklist. We use it for gear fit talks.

Freight details (measure, don’t guess):

- Length, width, height of the largest piece (and total footprint if multiple pieces)

- Total weight and the heaviest single piece weight

- Piece count and whether items are palletized, crated, or loose

- Center of gravity concerns for tall or top-heavy equipment (if known)

Handling and access:

- Loading method: dock, forklift, overhead crane, or drive-on/drive-off

- Side/top access needed: yes/no

- Pickup/delivery site limits: yard space, ramp availability, ground conditions

Protection and constraints:

- Need for enclosure: weather, theft, contamination control

- Temperature control required: yes/no and target range if yes

- Fragility: whether straps/edges/tarp contact can damage the cargo

Say “it’s heavy” or “it’s long”? Carrier asks more. It delays. Give the list. Match becomes fast. It stays reliable.

How to Choose the Right Trailer for Your Freight

The best trailer meets cargo needs. It adds least hassle. Start with simple gear. It must meet shield, height, and load access. Step up to special only if freight demands.

- Step 1: Decide enclosure vs open deck: Does cargo need weather shield? Road debris shield? Theft shield? Start with dry van or reefer. Is cargo irregular? Heavy? Needs side/top load? Start with flatbed family.

- Step 2: Use height to separate flatbed vs step deck vs lowboy:Load fits standard height on flatbed? Standard flatbed is simple. Too tall on flatbed but not extreme? Step deck next. Very tall? Lowboy fits.

- Step 3: Use loading method to choose RGN vs “lift-on” equipment: Cargo self-propelled? Can drive? RGN cuts cranes. It eases site plan. Must lift? Flatbed/step deck/lowboy depend on height and securement.

- Step 4: Use length to decide if you need an extendable deck: Freight exceeds standard deck? Avoid unsafe overhang? Extendable flatbed or RGN fits.

- Step 5: Choose protection style for open-deck freight: Need open-deck access? Want built-in shield? Conestoga or curtainside cuts tarping time. It boosts consistency. When available.

A common error is picking “what we used last time.” Skip actual limits. Shipment changed? Height? Load method? Shield needs? Change trailer too.

Cargo Securement Basics by Trailer Type

Securement is key. It is part of gear fit. Cannot secure well? Physical fit does not matter.

- Flatbed and step deck:They use strap/chain securement. Add edge protection. Plan tie points. Use right straps or chains. Add tarps for weather. Goal is no movement. Under brake, turn, wind.

- Lowboy and RGN:Heavy gear securement uses chain points. Machine tie spots. Control articulation. For RGNs, check room and ground for drive-on. For lowboys, load sits right in well. Avoid unstable weight.

- Curtainside and Conestoga:They give built-in shield. Still need inside securement. Curtains and canopies block weather. They do not stop shift.

- Enclosed (dry van, reefer):Enclosure cuts weather risk. Cargo can shift. Plan block/brace as needed. Check load method and dock fit. For reefers, guard temperature at load and unload. Avoid quality loss.

Unsure on securement? It signals wrong trailer. Or need better plan for ties and packing.

Conclusion

The right trailer starts simple. Match freight shield needs. Height. Load access. Enclosed trailers fit pallet and protected freight. Dry vans and reefers. Open-deck fit heavy, tall, long, or irregular cargo. Flexible load. Flatbeds, step decks, lowboys, RGNs, extendables.

Take one step from this guide. Use shipment checklist before book. Give clear size, weight, load method. Cut delays. Stop damage. Ease the move. No matter the trailer.

FAQ

What is the main difference between a dry van and a flatbed?

Dry van is enclosed. It suits pallet or box freight. It loads from rear. Flatbed is open. It suits heavy, irregular, or oversize freight. It needs side/top access. Cargo needs weather/theft shield? Fits fixed size? Dry van is simple. Load access or shape limits? Flatbed wins.

When should I choose a reefer instead of a dry van?

Choose reefer for temperature control. Or when shipper demands for product safety. Dry van cannot hold set temperature. It fails for cold-chain. Expect less inside space in reefers. From insulation and unit.

Step deck vs flatbed: which one should I book for tall freight?

Book step deck for loads too tall on flatbed. Not tall enough for lowboy. Step deck lowers main deck. It adds height clearance. No need for heavier special trailer. Still too tall? Go to double drop/lowboy.

What is the advantage of an RGN for equipment moves?

RGN allows drive-on. Remove gooseneck. Cuts need for cranes or big forklifts at site. Useful for self-propelled machines. Remote spots with little handling gear. Check ground and space for load process before book.

Do I need an extendable trailer for long freight?

Need extendable deck for freight over standard length. Avoid unsafe overhang. Extendable flatbeds and RGNs support long cargo. Better balance. Better securement. Choice depends on height and load method.

What shipment details should I send to pick the correct trailer quickly?

Send largest piece length/width/height. Total weight. Heaviest piece weight. Piece count. Load method (dock, forklift, crane, drive-on). Add shield needs like enclosure or temperature. Facts clear? Trailer type obvious.