Pick the trailer that fits your cargo, site, and risk level. Do not pick one that just sounds safe. At Genron, we make custom semi-trailers. We see these choices in real work schedules. A flatbed saves time. It lets you haul more types. An enclosed trailer cuts damage. It lowers theft risk.

This guide is practical. We compare flatbeds and enclosed trailers. We use the same rules we share with customers. You will get a clear way to choose. You will also get a short list of details to check before you buy, rent, or spec a trailer.

Table of Contents

What I Ask Before Recommending a Trailer?

Answer key questions in order to pick fast. Start with cargo facts. Then check your loading site. Last, look at cost and how often you use it. If you mix up the order, you fix the wrong part.

First, describe the cargo as shipped. Use real size, weight, shape, and lift spots. These decide if it fits. They decide safe handling. Value and how fragile it is set protection needs. They set the cost of a small problem.

Second, check the loading and unloading site. A dock with pallet jacks differs from a job site with cranes, mud, and no ramp. Site facts set your access. They set equipment choices. They set time lost if loading is one way only.

Third, be real about your tie-down skills. Flatbed work needs more than straps and chains. It needs checks, good tie points, edge guards, tarp rules, and driver care at stops. If your team lacks this, risk goes up. This happens even if the trailer is strong.

Last, do the ownership math. A trailer used twice a year acts like stored gear. It is not a daily tool. Low use makes upkeep, storage, and fees feel big. Renting often makes sense then.

Here is a simple checklist to use before you pick:

| Decision factor | What you must confirm | Why it changes the choice |

|---|---|---|

| Cargo size, shape, weight | Longest, widest, tallest point; lifting method; weight concentration | Determines fit, loading method, and whether enclosed constraints block the job |

| Sensitivity and value | Weather sensitivity, cleanliness needs, theft risk, damage cost | Determines how much “protection” is worth paying for |

| Loading environment | Dock vs job site; crane/forklift access; approach space | Determines whether you need multi-direction access |

| Usage frequency | Weekly vs seasonal vs one-off | Drives “buy vs rent” and the tolerance for operating effort |

| Securement capability | Straps/chains inventory; tie-down points; tarp workflow; inspections | Determines whether flatbed risk is manageable |

If you answer these clearly, the choice is clear. Details then move from type to specs.

Why choose a flatbed trailer?

Use a flatbed trailer truck for oversized, odd, heavy loads. Or for loads that need access from many sides. You must handle exposure and tie-down rules. You gain from open access. You accept the duties. When both fit, a flatbed beats others for speed and options.

The main win is access. Load from the side, rear, or top. Forklifts and cranes work easy. The trailer does not limit you to one path. For building supplies, machines, steel, prefab parts, and industrial loads, this speeds work.

Flatbeds take odd shapes well. They have no fixed box. A load too tall, wide, or with bumps may not fit enclosed. Weight may be fine. On flatbed, limits are road rules and safe ties. Not inside shape.

From a build view, flatbed is a strong base. Frames are steel or aluminum. Decks are wood or metal based on job and setting. For us, custom work hits key spots. These are deck size, stake pockets, rub rails, winch tracks, lashing rings, and tie points. These details speed safe ties.

Tradeoffs exist. Weather is first. Cargo faces rain, snow, sun, and spray. Tarps help many loads. But tarping takes work and time. It works only if done right. Some cargo hates moisture or dirt. This turns a cheap trip to a big claim.

Security is second. Open cargo shows. This draws eyes at stops. Theft may not be main worry. But tampering and lost items rise. If you stop overnight often, or park in unsafe spots, add this risk to choice.

Tie-down is third and key. It is a full system. Pick right tools. Use edge guards. Anchor to good points. Balance load. Check after first miles and at stops. If your steps are weak, flatbed risks more despite options.

Think of flatbeds this way. They let you haul more. But you control more. If you have people and habits to control it, wins beat costs.

Why choose an Enclosed Trailers?

Use an enclosed trailer for cargo that must stay clean, dry, and hidden. The load must fit inside and door size. Key is fit. Enclosed protects well. But it cannot add space for big shapes. When cargo fits and needs guard, it cuts work headaches.

The main value is protection. Walls and roof block rain, debris, dust, and spray. For electronics, furniture, boxes, show gear, tools, and high-value items, this stops damage. It cuts rework. It makes delivery steady. Weather matters less.

Security is next big value. Cargo hides. Doors lock. This does not stop all theft. But it shifts risk. This helps at hotels, stops, and sites with no watch. Many use it as mobile storage. This cuts need for extra space on jobs.

Containment is a missed win. Small items stay in. They do not blow out or shift off. This eases work for mixed loads with many parts. Not one big machine. It keeps areas clean when you set tools or spares.

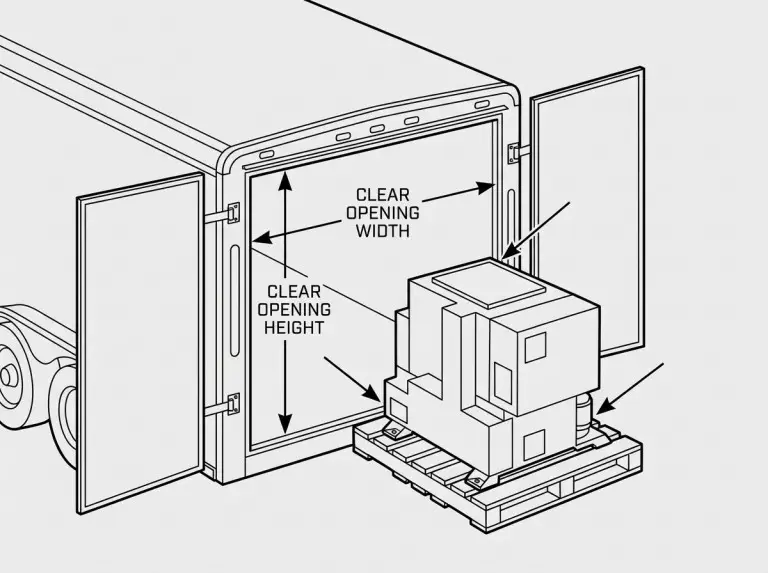

Limits are clear. Common error is overall length. Ignore door, width, height inside. A machine fits on paper. But door is too narrow. A pallet fits in. But access is hard without dock or ramp.

Access slows loading. Many use rear door. Some have side doors. But path is tight vs flatbed. If you need side or top lift, it adds steps. This adds time and risk.

Weight limit can bind vs same size flatbed. Walls add weight. This cuts payload. It nears tow limits. Do not guess. Check tow setup and full weight.

One caution. Some think enclosed controls temp or humidity. It mainly shelters. It cuts direct hit. But no control unless you add gear and steps. If cargo needs control, set that separate. Be clear on protection.

Enclosed trailers ease guard and security. But check fit. Accept access limits.

Flatbed Trailers vs. Enclosed Trailers: How to Choose

Pick fast by comparing both on four areas. These are cargo fit, site, risk, and cost. Best is the one that wins your key areas.

Use this matrix as guide. It does not replace checks. But it stops single-factor picks like price.

| Category | Flatbed tends to win | Enclosed tends to win |

|---|---|---|

| Cargo fit | Load is oversized, irregular, heavy, or needs crane/forklift side access | Load fits interior + door opening and benefits from a protected interior |

| Loading site | Job sites, yards, no docks, multi-direction loading | Warehouse-to-warehouse, dock-friendly operations, controlled loading routes |

| Risk profile | Cargo is durable or can be tarped; securement skill is strong | Cargo is fragile, high-value, theft-sensitive, or must stay clean |

| Operating effort | You accept tarp and securement time to gain flexibility | You prefer simplified protection and containment with less exposure management |

If cargo is big and tough, flatbed is default. If delicate or valuable, enclosed is default. Gray area is mixed loads, varied sites, uneven security.

In gray, decide on site and team ties. If no docks or need side/top, flatbed wins flow. If overnight parks or high-value, enclosed wins security.

Here customization helps. For flatbeds, good ties and deck cut time and error. For enclosed, doors and inside ties cut friction and shift.

Total Cost and “Own vs Rent” Scenarios

Best pick matches your use pattern. Not lowest buy price. At Genron, we see regrets. Buy enclosed for security but fight loading. Or buy flatbed cheap but miss labor for ties. Both ignore full work facts.

Start with direct costs. Flatbeds cost less at start. They can be lighter. This helps tow fuel. But need ongoing buys for tarps, straps, chains, guards, hardware. Cost is cash and time. Tarping and ties add work. Work is real cost.

Enclosed cost more at start. May raise fuel from weight and drag. Based on tow. But cut damage, cleaning, theft. This saves on real risk jobs. They ease staging. Tools stay in between stops.

Then think upkeep and storage. All need tires, bearings, lights, brakes, hardware checks. Low-use still costs. Age, storage, neglect cause fails. If use once or twice a year, storage and sit costs add. Renting wins.

Here are three use cases:

- High-frequency, mixed cargo (weekly or more). Owning fits. Dispatch options matter. Many gain from both types. Own one and rent other as needed. Or own both if cargo steady.

- Mid-frequency, specialized loads (monthly). Pick for main money loads. If most are site drops and odd cargo, flatbed pays back fast. If packaged or high-value with security, enclosed fits better.

- Low-frequency, event or seasonal use (a few times per year). Renting can win. Storage and unused upkeep add. If want own, be real on space, rules, time to keep ready.

Last, see buy vs rent as option tool. Not pride. Rent fixes one job without wrong gear lock. Owning helps when routes and cargo steady.

Conclusion

The right choice is simple. Pick a flatbed when the job demands open access and irregular loads. Pick an enclosed trailer when protection and concealment matter. The cargo must fit the box and door constraints. If you are unsure, answer the checklist questions in order. Let cargo reality and job-site handling decide first. Then confirm total cost and usage frequency.

At Genron, we build custom semi-trailers. We support customers who haul different cargo through changing conditions. If you share your cargo profile and loading environment, we can help you confirm the right trailer direction. We can help with the practical spec details that make the job easier day after day.

FAQ

What are the key differences between a flatbed and an enclosed trailer?

A flatbed gives open access for oversized or irregular loads. An enclosed trailer provides protection and concealment for sensitive or valuable cargo. Flatbeds trade protection for flexibility. Enclosed trailers trade flexibility for protection. The correct choice depends on cargo fit, loading environment, and risk tolerance.

How do I choose the right trailer for hauling construction materials?

A flatbed is usually the best fit for construction materials. Job sites often need side or top loading. The cargo can be irregular or oversized. If the load includes sensitive equipment that must stay clean or dry, an enclosed trailer can still be a better match. The equipment must fit. Loading access must be practical. In mixed cases, prioritize the loading site and handling method first.

What do tarps actually solve on a flatbed trailer?

Tarps mainly reduce weather and road-spray exposure. But they do not eliminate all risk. They require correct installation to work. They also add time and physical effort. Poor tarping can create damage through flapping or trapped moisture. Treat tarping as a workflow with proper securement. Not as a quick cover.

Can an enclosed trailer be used for hauling large machinery?

Yes, but only when the machine fits both the interior space and the door opening. You must load it safely using your available equipment. Many large machines fail the door-width or height constraint. Even if the trailer length looks sufficient. Always confirm the loading path. Not only the interior dimensions.

How do I ensure safe loading and unloading on either trailer type?

Start by matching the loading method to the trailer access. Flatbeds support side/top loading. Enclosed trailers often require rear access. Then control weight distribution. Prevent movement using appropriate tie-down points and securement devices. After the first miles, re-check the load. Settling is common on real roads.

Are enclosed trailers always more secure than flatbeds?

Enclosed trailers are generally more secure. Cargo is out of sight. Doors can be locked. But security still depends on stops, parking, and habits. A visible flatbed load can attract attention. Yet strong securement and smart routing can reduce risk. Choose based on the value of the cargo. And how often it will be unattended.